Specifications

SCH80

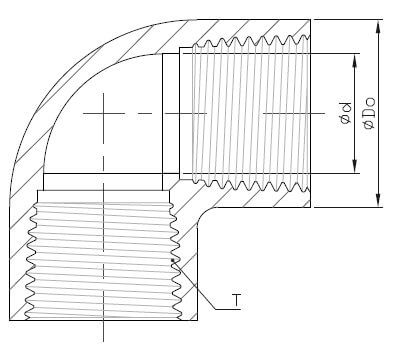

90o Elbow(S*S)

|

Size |

Outside Dia |

Socket Type |

Structure Diameter |

|||

|

D0 |

d1 |

d2 |

l |

d |

G |

|

|

1/2″ |

30.5 |

21.54 |

21.23 |

22.22 |

16.5 |

12.8 |

|

3/4″ |

38 |

26.87 |

26.57 |

25.4 |

22 |

15.3 |

|

1″ |

46 |

33.66 |

33.27 |

28.58 |

28 |

18 |

|

1-1/4″ |

55 |

42.42 |

42.04 |

31.75 |

35 |

23 |

|

1-1/2″ |

60 |

48.56 |

48.11 |

34.93 |

43 |

26 |

|

2″ |

75 |

60.63 |

60.17 |

38.1 |

54 |

32 |

|

2-1/2″ |

90 |

73.38 |

72.85 |

44.45 |

69 |

38 |

|

3″ |

107 |

89.31 |

88.70 |

47.63 |

84 |

48 |

|

4″ |

133 |

114.76 |

114.07 |

57.15 |

105 |

59 |

|

5″ |

163.5 |

141.81 |

141.05 |

66.68 |

136 |

80 |

|

6″ |

191 |

168.83 |

168.00 |

76.2 |

150 |

89 |

|

8″ |

246 |

219.84 |

218.69 |

101.6 |

200 |

115 |

|

10″ |

306.5 |

273.81 |

272.67 |

127 |

265 |

150 |

|

12″ |

364 |

324.61 |

323.47 |

152.4 |

315 |

180 |

|

14″ |

396.5 |

356.49 |

355.22 |

*180 |

346 |

248 |

(Unit : mm)

Note : Do not comply with ASTM standards, if mark with *.

90o Elbow (S*T)

|

Size |

Outside Dia |

Socket Type |

Structure Diameter |

|||

|

D0 |

d1 |

d2 |

l |

d |

NPT(thd./in) |

|

|

1/2″ |

30.5 |

21.54 |

21.23 |

22.22 |

16 |

14 |

|

3/4″ |

38 |

26.87 |

26.57 |

25.4 |

22 |

14 |

|

1″ |

44 |

33.66 |

33.27 |

28.58 |

28 |

11.5 |

|

1-1/4″ |

54 |

42.42 |

42.04 |

31.75 |

35 |

11.5 |

|

1-1/2″ |

60 |

48.56 |

48.11 |

34.93 |

43 |

11.5 |

|

2″ |

73 |

60.63 |

60.17 |

38.1 |

54 |

11.5 |

(Unit : mm)

90o Elbow (T*T)

|

Size |

Outside Dia |

Structure Diameter |

|

|

D0 |

d |

NPT(thd./in) |

|

|

1/2″ |

30.5 |

16 |

14 |

|

3/4″ |

38 |

22 |

14 |

|

1″ |

44 |

28 |

11.5 |

|

1-1/4″ |

54 |

35 |

11.5 |

|

1-1/2″ |

60 |

43 |

11.5 |

|

2″ |

73 |

54 |

11.5 |

SCH40

90o Elbow (S*S)

|

Size |

Outside Dia |

Socket Type |

Structure Diameter |

|||

|

D0 |

d1 |

d2 |

l |

d |

G |

|

|

1/2″ |

27.5 |

21.54 |

21.23 |

17.48 |

18 |

12.7 |

|

3/4″ |

33.6 |

26.87 |

26.57 |

18.26 |

22.5 |

14.8 |

|

1″ |

41.7 |

33.66 |

33.27 |

22.23 |

29 |

18.3 |

|

1-1/4″ |

50.5 |

42.42 |

42.04 |

23.83 |

38 |

22.7 |

|

1-1/2″ |

56.8 |

48.56 |

48.11 |

27.79 |

43.5 |

25.7 |

|

2″ |

69 |

60.63 |

60.17 |

29.36 |

55 |

32 |

|

2-1/2″ |

84.2 |

73.38 |

72.85 |

44.45 |

67.5 |

39 |

|

3″ |

100.8 |

89.31 |

88.70 |

47.63 |

83.5 |

46.5 |

|

4″ |

127.3 |

114.76 |

114.07 |

50.8 |

108.5 |

59.7 |

|

16″ |

434.5 |

407.58 |

405.87 |

*205 |

376 |

240 |

(Unit : mm)

Note : Do not comply with ASTM standards, if mark with *.